Natural insulation, especially wood fibre, is experiencing a huge uplift in sales Will Kirkman from sustainable builder’s merchant Ecomerchant explains why wood fibre insulation’s popularity is on the rise.

Among its many great characteristics, wood has a long life, is highly durable and is easy to work with. It is also hygroscopic, which means that it has the capacity to absorb and release moisture without being damaged. It is this property that also makes wood an excellent insulation material.

Inhibiting and storing is how one might sum up the function of insulation made from wood fibre. A life cycle analysis (LCA) of wood products makes the advantages of the material even clearer. Wood is an important raw material, a socioeconomic treasure. It is a renewable resource, as long as the raw material is managed according to a consciously sustainable harvesting plan with responsibility for future growth, as is the case in European forestry. Look for certification either FSC the Forest Stewardship Council or PEFC the Programme for the Endorsement of Forest Certification, or both.

Buildings should be ventilated in a controlled way for the sake of the structure, the indoor environment, and for the building’s energy performance. Many homes do not suit our lifestyle every day functions, showering, cooking, central heating and laundry, for example produce significant quantities of water vapour so where the building has gaps (compounded by poor ventilation) letting air escape through the building envelope causes risk of condensation and subsequent damage or mould growth.

Older (leakier) homes were built for a very different way of living and often from locally sourced complementary materials. Naturally well ventilated they were colder and damper in the winter and dryer and warmer in the summer, but importantly often constructed form natural materials that had an inherent buffering capacity to deal with such moisture fluctuations without the threat to their structural integrity.

It has been the advent of synthetic and petrochemical materials that have removed the natural capacity of the building fabric to buffer moisture with a 100% reliance on ventilation to do all the work. Obviously this requires buildings to be both designed and built to a high standard and for them to be maintained as such in perpetuity but it also needs to accommodate the different ways in which occupants behave, in short it’s not a very forgiving way to build.

No one wants to live in a hermetically sealed plastic bag, and we all want our lifestyles to be accommodated by our homes without the threat of damage to the building fabric. Older homes have intrinsic appeal to many often draughty, but none the less a pleasant house one can trust. But those houses are also no good for today’s modern lifestyle, since letting damp, warm air pass out through the building envelope may prove harmful for the building shell or the indoor environment. In addition, the operating cost, comfort and environmental impact of heating a draughty house is generally problematic.

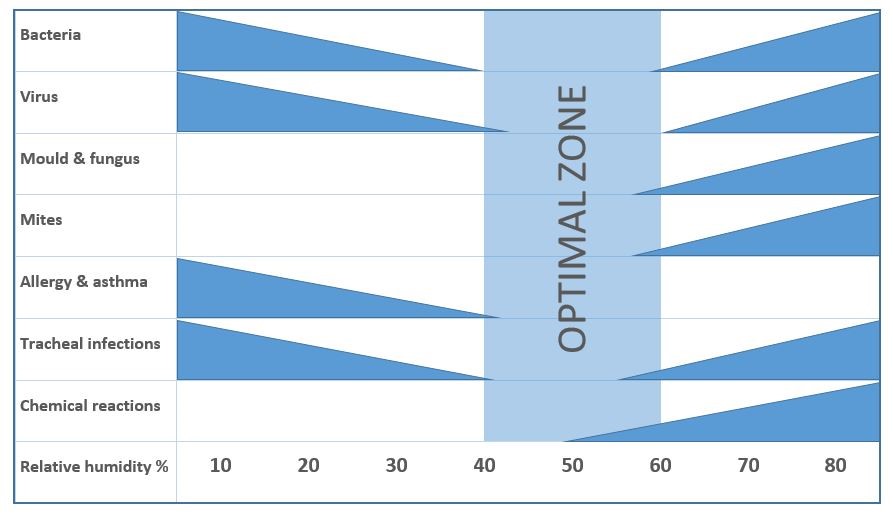

A negative experience of the indoor environment also comes down to the same issue, the inability of the constituent materials to absorb and release moisture. We simply don’t feel as well in houses that lack the ability to buffer and release a healthy amount of moisture into our living environment. Our mucous membranes, but also our skin, need moisture – a relative humidity figure (RH) of between 40 and 60 percent is optimal – to protect the body and the immune system against unwelcome attack.

Simplicity of Construction

The use of mineral wool (vitreous) or PUR foil backed boards requires the use of vapour barriers to prevent air leakage from the interior causing condensation in the structure. Rigid insulation boards must be cut very accurately to fit between timber structures with all of the joints taped and all junctions sealed. The security and durability of the seals and vapour control becomes more important as insulation levels increase levels meaning a corresponding increase in condensation risk.

On a timber frame (wall or roof) synthetic insulation materials require breather membranes, ventilated cavities and either tile battens, cladding battens or render carrier boards to finish. Construction must allow for the timber to be able to shrink and move whilst still staying weather and wind tight.

Choosing wood fibre insulation simplifies the construction process by allowing less a complex timber structure to be used. It requires fewer layers and does not require any cavities (except an internal service void or behind a ventilated rain screen such as timber cladding or if using a non-wood fibre render carrying board). To eliminate the need for a cavity on the external side a wood fibre render carrying board, such as Steico Protect, is directly fixed to the timber frame with render applied to the external face. Wood fibre used in this way significantly lowers thermal bridging plus the overall wall thickness is rarely thicker and may even be thinner.

Internal walls can be faced with a rigid wood fibre board, between studs can be full filled with flexible wood fibre batts or blown wood fibre floc. Flexible wood fibre batts are self-supporting dense form of wood fibre which can be friction fitted between studs ensuring a snug fit with no gaps. Its hygroscopic nature makes it much safer to use than mineral wool or rigid synthetic PUR boards as it allows the frame to dry quickly once weathertight, preventing mould formation and rot occurring.

Alternatively specifically designed internal racking boards can be used to provide strength, airtightness and as a vapour control layer, for example Durelis VapourBlock. If using an airtight board ensure the joints taped with an airtight tape such as Pro Clima Tescon Vana which will ensure very high levels of air tightness, even as the timber frame shrinks.

Most roof applications over 16 degrees do not require an external membrane if using a wood fibre board offering another saving in cash and labour. Steico wood fibre boards can be left exposed for up to 8 weeks on site.

Most wood fibre boards use a tongue and groove profile to ensure weather tightness but also wind tightness. They are highly vapour permeable, ensuring that no construction moisture gets trapped in the finished building and that the timber frame remains dry.

Small air leaks in the envelope of the building can transport large amounts of moisture into the fabric of the building during the winter months. Wood fibre insulation is not only vapour permeable but very capillary active, meaning it can transport moisture very quickly down each wood fibre. This ensures that any moisture leaking in to the fabric of the building can be quickly dispersed and allowed to evaporate from the exterior of the building.

Increasing simplicity also ensures that the building is built as designed and therefore performs as designed, eliminating the well-known ‘performance gap’.

Wood fibre offers two more significant bonuses when use in timber frame construction, in improved acoustic insulation and reducing or eliminating overheating risk. This is valuable as even in traditional block and brick construction a portion of the living space will often be timber frame when creating a warm roof to maximise space. A standard timber frame wall build-up will typically offer noise reduction of around 50dB, making most common traffic and weather noise inaudible. The most common remark people make when entering buildings with wood fibre insulation is how quiet they are.

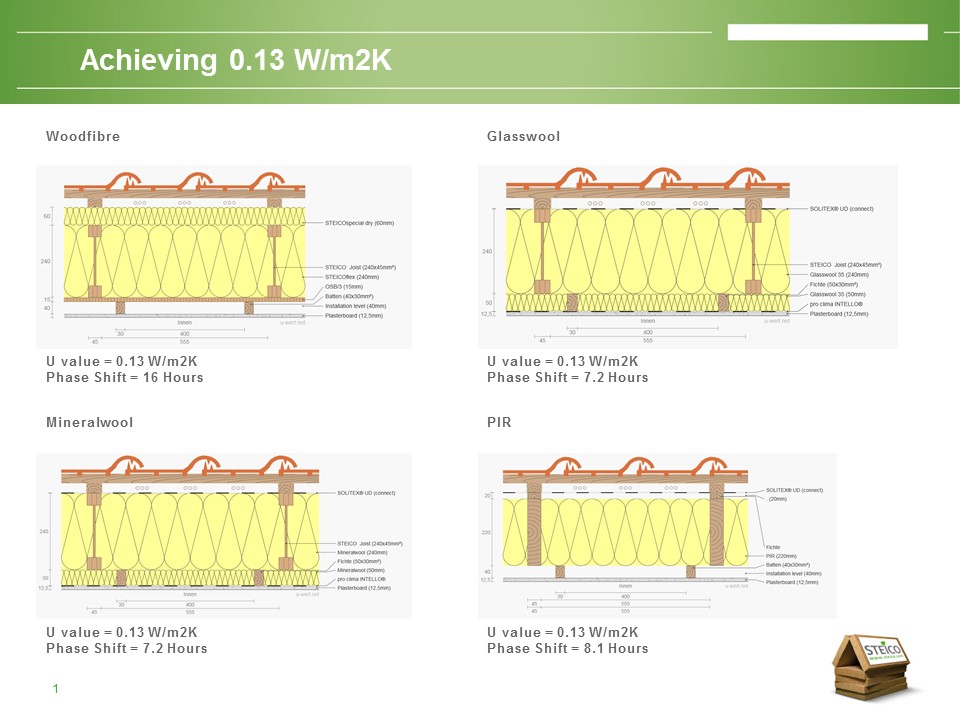

Flexible wood fibre insulation stores around 20 times more heat energy than the equivalent volume of glass or mineral wool. Typical wood fibre boards will store around 12 – 15 times more heat energy than foam boards. This ensures that the internal temperature stays very stable all year round and little of the summer sun’s heat passes through the walls to cause overheating.

Human health:

Wood fibre can also have the IBR seal of approval which was created by the Institut für Baubiologie Rosenheim GmbH in 1982 to raise consumer’s awareness of health and ecological matters and to protect themselves against health hazards caused by building materials and furniture in the built environment.

The seal of approval is awarded to products which ensure healthy living and at the same time protect the environment. Besides its focus the potential physiological effect on human health the certification also includes assessment of impacts derived from processing, use and recycling ensuring no adverse effects on the environment.

Products that emit harmful substances, i.e. carcinogenic and/or mutagenic cannot be certified under any circumstances.

Ecomerchant are UK distributors for Steico wood fibre insulation products. All Steico products are certified to FSC or PEFC standards with full chain of custody paperwork have an Environmental Product Declaration (EPD) are IBR certified and are Certified Passive Components.

Find out more at www.ecomerchant.co.uk email info@ecomerchant.co.uk or call 01793 847 444